It’s hard to think of a home improvement project that doesn’t involve sandpaper. Woodworkers use it to smooth and shape wood. Painters and refinishers need it to remove old finishes and polish new ones. Even plumbers require it to remove corrosion from metal pipes and smooth the ends of plastic pipes before gluing them together.

If you’re doing drywall work or cleaning old grout, you’ll need it, too. You can even use it in a pinch to sharpen tools or file your fingernails!

Because it has so many uses, it’s not surprising that sandpaper comes in multiple forms. Variations include:

- Abrasive material used;

- Type of backing;

- Format (sheet, belt or disk) for specific sanding machines.

Grit is one of the most important variables. Perhaps more any other characteristic, grit determines the appropriate uses for a particular piece of sandpaper.

On This Page

What Is Sandpaper Grit?

Grit measures sandpaper’s coarseness, determined by the size of the abrasive particles on its surface.

A coarse grit wears down whatever you’re sanding more quickly, but it also leaves deep scratches. Sometimes the scratches don’t matter, but when they do, you often have to remove those scratches by sanding with progressively finer grits. Woodworkers, flooring installers and furniture refinishers call that process “going through the grits.”

The Coated Abrasive Manufacturers Institute (CAMI) and the Federation of European Producers of Abrasives (FEPA) regulate sandpaper grit standards. They refer to the size and number of holes in the screens that filter the abrasive particles.

Large particles fit through larger holes. Because they’re larger, a standard filtering screen requires fewer of them. Consequently, coarser grits are known by smaller numbers than finer grits, much like larger-diameter wires have smaller gauge numbers in the American Wire Gauge system.

The CAMI and the FEPA use different grit numbers, and those of the latter are typically preceded by the letter “P.” In the CAMI system, sandpaper grits range from 24 to 1,000 (and sometimes higher), which corresponds to P12 to P2,500 in the FEPA system. The CAMI system predominates in North America.

Grits Are Categorized Into Grades

While it’s theoretically possible to manufacture sandpaper grits in tiny progressions, it would be impractical and confuse customers. Consequently, grit numbers increase by standard intervals. The higher the number, the finer the grit. Coarse grits progress from 24 to 30 to 36, while fine ones rise from 600 to 800 to 1,000 and beyond.

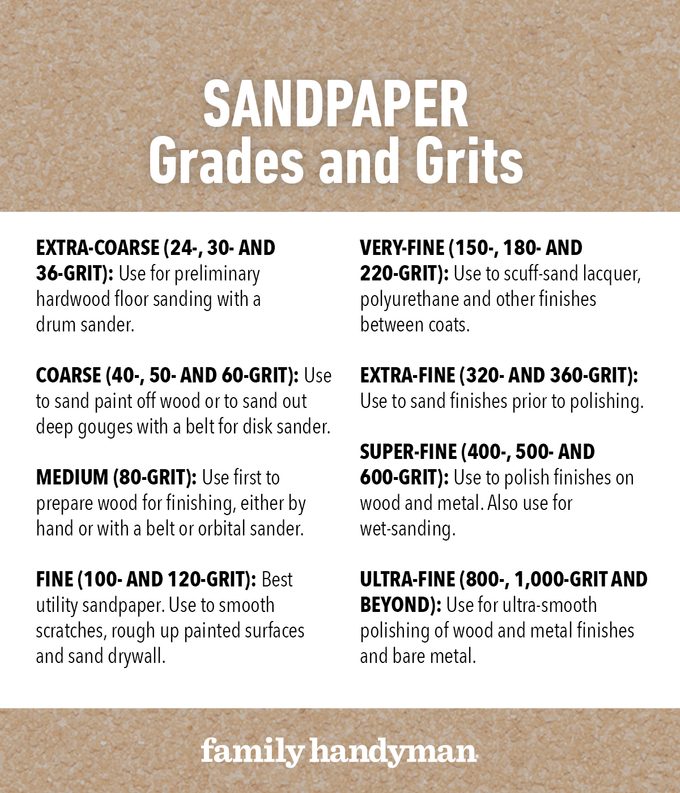

Because coarse and fine sandpaper grits are used differently, manufacturers established grades — each consisting of one or more grit numbers — to help consumers decide which type fits a particular purpose. The coarsest grade, designated as extra-coarse, includes 24-, 30- and 36-grit paper. The finest grade (i.e. ultra-fine) includes 800- and 1,000-grit paper.

When choosing sandpaper, it’s important to select the right grade for the job. A paper that’s too coarse will leave the surface scratched and damaged, while one that’s too fine won’t do the job. Extra-coarse and ultra-fine grades are generally reserved for rough sanding and polishing. A medium or fine grade works best for most projects around the house.

Sandpaper Grades and Grits

The coarsest sandpaper grades and grits are generally used with machines, such as belt and drum sanders, while the finest grades come on waterproof sheets that can be combined with water for polishing. Medium and fine grits are available on 9- x 11-inch paper or cardboard sheets, or on precut backings for machines like detail or random orbital sanders.

The grades and grits you’ll find at hardware stores include:

- Extra-coarse (24-, 30- and 36-grit): Generally used for preliminary hardwood floor sanding, this usually comes in belts that fit on a drum sander, or disks that fit an edger.

- Coarse (40-, 50- and 60-grit): Coarse grits remove a lot of material quickly, like sanding paint off wood or sanding out deep gouges. Coarse grades are available in 9- x 11-inch sheets, belts for drum and belt sanders, and disks for disk sanders.

- Medium (80-grit): This is often the first grade chosen when going through the grits to prepare wood for finishing. Use it to hand sand, or with a belt or orbital sander. It’s also good for removing rust and corrosion from metal.

- Fine (100- and 120-grit): The best utility sandpaper. Fine grades smooth scratches left by coarser grades and rough up painted surfaces before accepting new paint. They’re also good for sanding drywall. When you just need some for hand-sanding, or to use with an orbital sander, this is the grade you’ll most likely use.

- Very-fine (150-, 180- and 220-grit): This produces ultra-smooth surfaces on wood. People often use it to scuff-sand lacquer, polyurethane and other finishes before applying another coat.

- Extra-fine (320- and 360-grit): The first of the micro-abrasives, this is primarily for sanding finishes before polishing.

- Super-fine (400-, 500- and 600-grit): Use this for polishing finishes on wood and metal, and to polish bare metal. It comes on waterproof sheets to allow for wet-sanding.

- Ultra-fine (800-, 1,000-grit and beyond): Use this grade for ultra-smooth polishing of wood and metal finishes and bare metal.

Did you miss our previous article…

https://tophouseimprovement.com/how-to/lilac-bush-or-lilac-tree-key-differences/